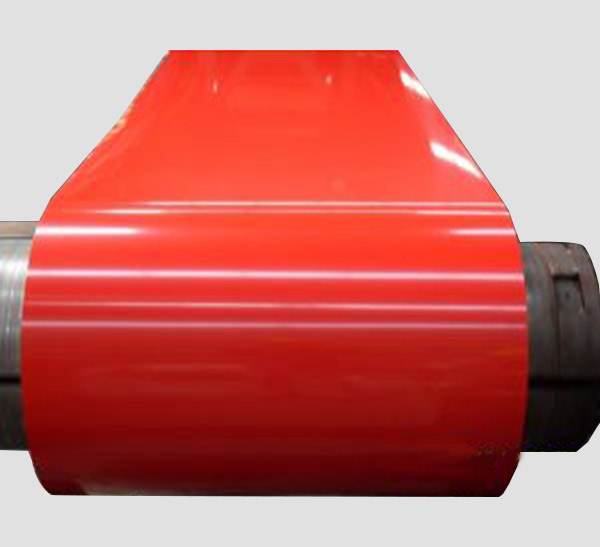

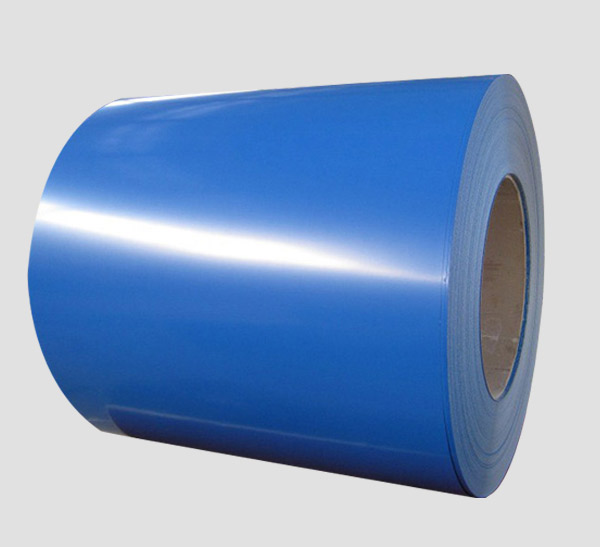

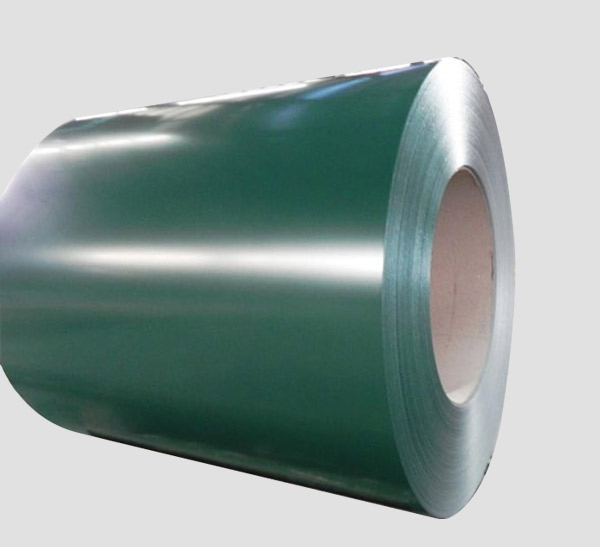

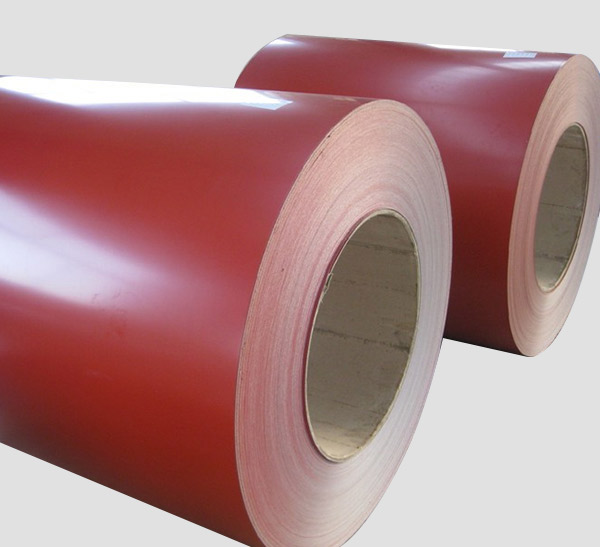

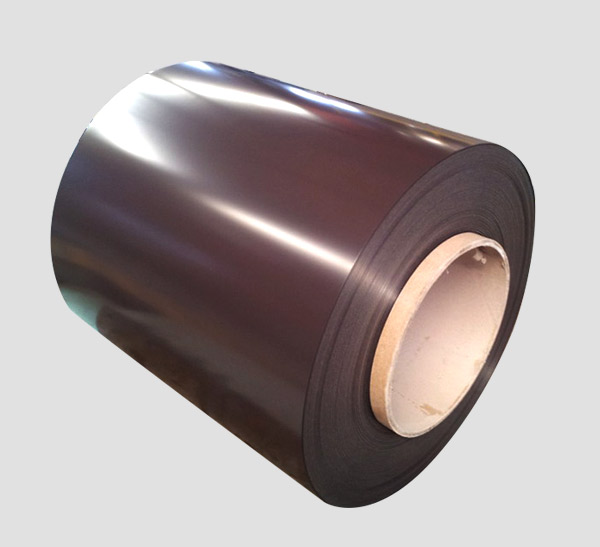

PREPAINTED STEEL COIL/SHEET

PREPAINTED GALVANIZED STEEL COIL(PPGI)

-

hot dipped galvanized, galvalume, zinc alloy, cold rolled steel, aluminum

-

S G3322 CGLCC ASTM A755 CS-B

-

0.16-1.2mm

-

359 ton

PRODUCT INQUIRY

Custom PREPAINTED GALVANIZED STEEL COIL(PPGI) sizes available upon request.

Product Description

Images & Video

Applications

Our Advantage

| Standard | JIS G3322 CGLCC ASTM A755 CS-B | Surface coating color | RAL colors |

| Back side coatingcolor | Light grey ,white and so on | Package | export standard package or as request |

| Type of coating process | Front: double coated&double drying. Back: double coated&double drying, single-coated&double drying | ||

| Type of substrate | hot dipped galvanzied, galvalume, zinc alloy, cold rolled steel, aluminum | ||

| Thickness | 0.16-1.2mm | Width | 600-1250mm |

| Coil Weight | 3-9Tons | Inside Diameter | 508mm Or 610mm |

| Zinc Coating | Z50-Z275G | Painting | Top: 15 to 25 um (5 um + 12-20 um) back: 7 +/- 2 um |

| Coating introduction | Top paint: PVDF, HDP, SMP, PE, PU | ||

| Prime paint: Polyurethane, Epoxy, PE | |||

| Back paint: Epoxy, Modified polyester | |||

| Productivity | 150,000Tons/year | ||

| Production core strengths | |||

| Resistance to acid rain: | |||

| Coating protection mechanism: It is very easy to form acid rain in the high level of industrial emissions or pollutants environment. Acidic penetration is formed in the surface of pre-painted steel, and accelerates the corrosion, forming blistering, peeling and so on. | |||

| Resistance ultraviolet rays: | |||

| Coating protecting Mechanism: pre-painted sheet in ultraviolet or strong sunlight conditions, the coating will exhibit chalking degeneration, manifested as discoloration and loss of gloss, lose paint quickly. | |||

| Resistance to humid heat: | |||

| Coating protecting mechanism: in hot and humid environments, high osmotic pressure of water vapor accelerates penetration, forming the degeneration of painting film, then the corrosion of the substrate, with the phenomenon of bubbles and peeling. | |||

| Resistance to low temperature: | |||

| Coating protecting mechanisms: most of the paint can keep stable processing performance above 0 degree, but at alpine region, the temperature will be below 20-40 degree, normal paint will become brittle,bend cracking, or even lose paint, thus protection function is lost totally. | |||

Shandong Sino Steel Co., Ltd, founded in 1989, covers an area of 100,000 square meters, with more than 900 employees. Shandong Sino Steel is mainly engaged in producing and exporting galvanized steel coil/sheet(GI), prepainted galvanized steel coil/sheet(PPGI), corrugated galvanized sheet and tinplate coil/sheet. Shandong Sino Steel has also become the agent of hot rolled coil/sheet, cold rolled coil/sheet, I beam, angle steel and channel steel.

RETURN LIST

SEND EMAIL

-

PREPAINTED GALVANIZED STEEL COIL(PPGI)1

-

PREPAINTED GALVANIZED STEEL COIL(PPGI)1

-

PREPAINTED GALVANIZED STEEL COIL(PPGI)1

-

PREPAINTED GALVANIZED STEEL COIL(PPGI)1

-

PREPAINTED GALVANIZED STEEL COIL(PPGI)1